Ocado trials fruit-picking robot

- 31 January 2017

- Technology

OCADO

OCADO

Online grocer Ocado has shown off a soft robotic hand that can pick fruit and vegetables, without damaging them, in its warehouses.

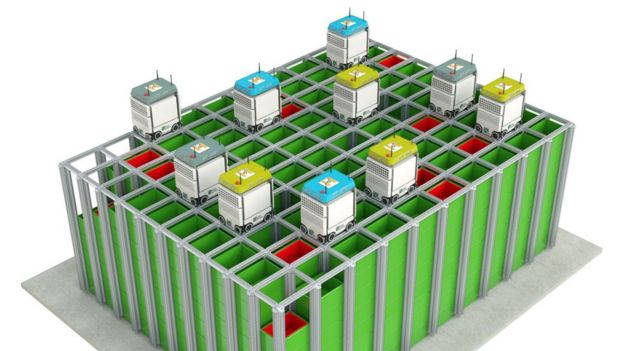

The firm has an automated warehouse in Andover, Hampshire, where robots select crates containing specific items that make up customer orders.

They are currently brought over to a human team for selection but, in future, the hand could replace them.

Also in development is a humanoid maintenance robot called SecondHands.

It will work alongside a human colleague to maintain the warehouse.

OCADO

OCADO

The fruit and vegetable picker is part of a five-year research EU-funded collaboration between five European universities and Disney called Soma (Soft Manipulation), said Ocado spokesman Alexandru Voica.

The demonstration device is an early prototype, he said.

"People have tried suction cups, robot hands with three fingers... What we are trying to do is to actually mimic the human hand.

"The gripper is based on air pressure, which controls the movement of the robotic fingers.

"What we are trying to do is combine computer vision - being able to recognise products by looking at them - with the control aspect which is the gripping aspect."

At the moment, only the gripper is being demonstrated but ultimately the robot will learn to distinguish fruit ripeness through machine learning.

It will also be able to pick other items which require different care - such as wine bottles and detergent.

"Fruit and vegetables are the hardest to pick," said Mr Voica.

"When the customer gets their bag of bananas or tomatoes, if they see the product is damaged they don't care whether it's a human or a robot that's picked it."

OCADO

OCADO

Prof Chris Melhuish, director of the Bristol Robotics Laboratory, said that building robotic devices - or manipulators - to carry out multiple tasks is difficult.

"A general purpose manipulator is a really tough thing to build, and certainly understanding and exploiting the way the human hand functions, because it is so flexible and adaptive, makes a lot of sense," he told the BBC.

"There are lots of groups that are looking at robotic manipulation but often it is for a specific purpose - picking up a concrete block is not the same as doing artificial suturing for example - so the tendency has been to build different types of manipulators for different domains."

![shrimp.jpg [Related Image]](https://newint.org/blog/2017/01/30/shrimp.jpg)

Starbucks unveiled a new third-party skill for Amazon Alexa this morning, letting regular customers reorder their favorite coffee and food by saying “Alexa, order my Starbucks” to a device powered by the online retail giant’s voice-enabled personal assistant.

Starbucks unveiled a new third-party skill for Amazon Alexa this morning, letting regular customers reorder their favorite coffee and food by saying “Alexa, order my Starbucks” to a device powered by the online retail giant’s voice-enabled personal assistant.